In today's world, having reliable network connectivity is more important than ever. Whether in commercial office spaces, data centers, or homes, the quality of the patch cables used can significantly impact the overall performance of a network. This is

where Black Box patch cables come into play. Unfortunately, many installers look at the patch cable as a consumable item. This is OK, but not all patch cables are made the same. For example, you need to question yourself: just because you have a Category

6 patch cable, do you really know if it is a high-quality cable? Here are some things to be aware of when selecting patch cable for your mission-critical network.

There are several very important factors to look at and be aware of when

purchasing patch cable from a supplier. This includes knowing the type and quality of the components used in the product of final patch cable assembly. For a typical patch cable, there are really only two major components used to assemble the

patch cable. These include the raw cable and the connectors. Generally speaking, all patch cables use some form of twisted-pair cable terminated with an 8-position RJ-45 connector on each end. Sometimes users overlook the connectors (which are RJ-45

plugs) and think that they are all the same, but this is not true.

Raw Cable – Quickly speaking, the raw cable is probably the most recognizable part of any patch cable assembly, because the cable is the biggest component of the overall assembly. In addition, the raw cable also has the cable category on the print legend, which identifies the type of cable. So, someone can easily tell the cable category by visual inspection.

Plugs – These are a bit more difficult to identify by visual inspection. All patch cables, regardless of the cable category, are terminated with RJ-45 plugs on each end. Many users think that they are all the same, but this is not true. Under quick inspection, all RJ-45 plugs basically look the same, plus, in addition, they normally do not have any markings to help identify which category standard the plugs comply with. For all RJ-45 plugs, the overall exterior shape must be the same and follow the IEC 60603-7 standard for compatibility between different manufacturers. But this is where the similarities end; the interior of the plug can vary from plug to plug, which can easily be overlooked.

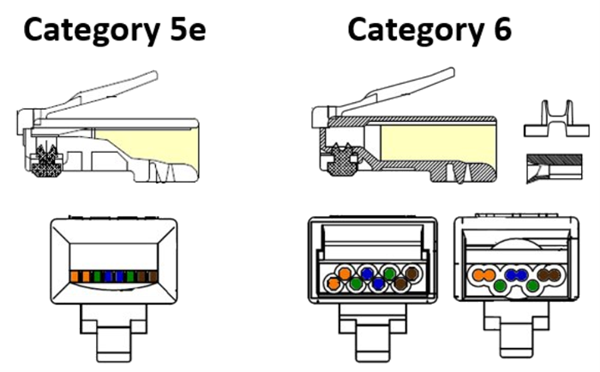

With that being said, there’s lots of technology inside the RJ-45 plug that may not get noticed. Here are some of the internal performance differences between Category 5e and Category 6 plugs.

Category 5e Plugs – These plugs are fairly simple and easy to terminate. These are usually a one-piece design that only includes the RJ-45 male plug body. Termination is done by stripping the raw cable and organizing the four colored pairs in the standard T568B wiring scheme. The internal cavity of the plug, shown in yellow, only allows the 8 individual wires to travel about halfway through the plug and align under each gold blade contact driver in a 1x8 row ready for crimping.

Category 6 Plugs - These plugs are more difficult to terminate and usually require additional skill. Because Category 6 technology is stricter than Category 5e, the interior of the plug is much different. Category 6 plugs typically have

an “open” internal cavity, shown in yellow, that allows the individual twisted pairs to travel much closer to the gold blade contact drivers. This keeps the twisted pairing of the raw cable passing through the plug in a more continuous

streamline of the pairing end-to-end throughout the patch cable. Also, another plug enhancement that improves performance is the use of a loading bar and/or pair spacers. Plugs using just a loading bar are referred to as 2-piece plugs, and plugs using

both a loading bar and pair separator are referred to as 3-piece plugs.

Load Bars – These are little pieces of plastic that attach to the end of the cable and help hold the four pairs in place as you begin to slide the cable for termination.

Pair Spacers – These are also small pieces of plastic that space out the four pairs inside the plug so they won’t touch. Spacing the pairs helps improve the NEXT “Near End Crosstalk” measurement, which is critical in improving performance.

Another design that Category 6 or higher-grade plugs use is a “stagger” or specialized aligned holes design that creates internal pair spacing inside the plug. This pair spacing improves NEXT (Near-End Crosstalk) and other electrical measurements.

All said, the use of open internal cavity plugs along with loading bars and pair spacers adds cost to the plug along with additional termination time and skill needed to assemble the patch cable. There is a lot of technology inside the plug of a patch cable that many users may not be aware of or don’t realize exists.

With all of this considered, it is good to be aware of and be able to view by inspection the type of components used by a supplier when you decide where to purchase your patch cable for your mission-critical networks.

Check out our CATx patch cable/plug offerings.

Product Engineer

Steve Molek has 27 years’ experience in the cabling and connectivity data communication industry. He started his career as a Technical Support Representative and now works as a Project Engineer for Black Box. As a Product Engineer, his primary focus is evaluating and testing all new cabling and connectivity products for sale by Black Box and training our inside technical support and sales teams. Steve also works directly with our domestic and international OEM suppliers as well as several nationally recognized third-party testing labs. Steve holds a B.S. degree in Mathematics and Computer Science from California University of Pennsylvania and an MBA from Waynesburg University.